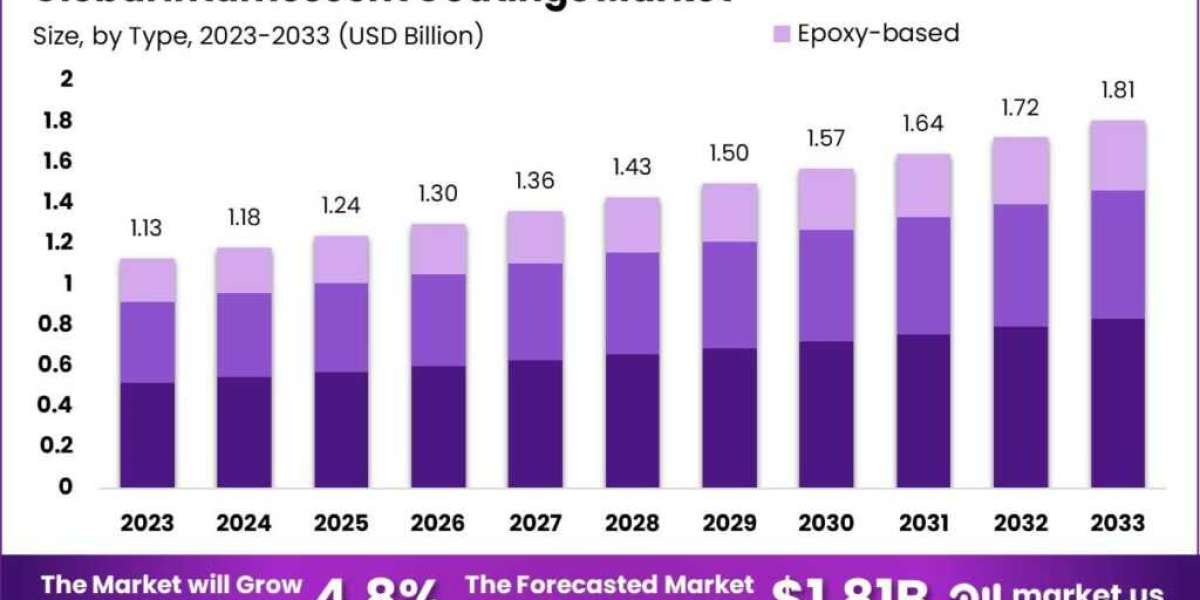

The Intumescent Coatings Market size is expected to be worth around USD 1.81 billion by 2033, from USD 1.13 Billion in 2023, growing at a CAGR of 4.8% during the forecast period from 2023 to 2033.

Intumescent Coatings Market refers to the global industry and economic sector involved in the production, distribution, and application of intumescent coatings. These are specialized coatings that expand when exposed to high temperatures, forming an insulating char layer that provides fire protection for structural materials such as steel, wood, and concrete. The market encompasses various segments based on coating types, substrates, end-use industries, and geographical regions. Key factors influencing the market include advancements in fire safety regulations, growing construction activities, increasing use of fire-retardant materials in various industries, and ongoing innovations in coating technologies.

Market Key Players :

- Akzo Nobel N.V.

- Jotun

- Contego International Inc.

- Hempel A/S

- No-Burn Inc.

- Nullifire

- The Sherwin-Williams Company

- Carboline

- Albi Protective Coatings

- Isolatek International

- Rudolf Hensel GmbH

- PPG Industries

- 3M

- Sika AG

- BASF SE

Click here for request a sample : https://market.us/report/intumescent-coatings-market/#requestSample

Market Segmentation :

Base :

In 2023, water-based intumescent coatings led the market with a 35.8% share due to their eco-friendly nature, low VOC content, and ease of application. These coatings, using water as the main solvent, emit fewer VOCs, pose less health risk, dry quickly, and require minimal cleanup. While not as heat-resistant as other types, they are ideal for situations where VOC emissions are a concern or for interior applications with moderate fire resistance needs.

Solvent-based coatings, known for their durability and resistance to harsh environments, contain higher VOC levels but excel in extreme conditions, making them suitable for high-heat areas and outdoor applications. Epoxy-based coatings, using epoxy resins, offer robust fire protection for critical applications like structural steel elements due to their strength and high-temperature resistance.

By Type :

Thin-film intumescent coatings held 53.8% of the market share in 2023, valued for their thin application and enhanced fire protection without compromising aesthetic appeal. They provide fire resistance without significant bulk, ideal for spaces where maintaining aesthetics or minimizing coating thickness is crucial.

Thick-film intumescent coatings offer strong fire protection through thicker layers, providing additional defense against fire hazards. These coatings are suited for heavy-duty applications requiring extra protection, such as environments with high temperatures or significant fire risks.

By Substrate :

In 2023, structural steel and cast iron dominated the intumescent coatings market with over 59% share. These coatings protect structural steel and cast iron elements in construction and industrial settings by expanding under high temperatures to form an insulating char layer, ensuring enhanced fire resistance. They are extensively used in commercial and industrial domains.

Intumescent coatings for wood provide fire-resistant properties by swelling and forming a protective layer when exposed to fire, delaying flame spread. These coatings are crucial for residential and commercial construction to ensure the fire safety of wooden structures.

By End-use Industry :

The building and construction sector led the intumescent coatings market in 2023 with over 38.8% share. These coatings enhance fire safety by forming an insulating char layer on structural materials like steel and wood, significantly contributing to building fireproofing and compliance with fire regulations.

In the automotive industry, intumescent coatings protect vehicle parts from extreme heat, providing additional fire protection for components and occupants. In the oil and gas industry, these coatings safeguard structures and equipment from high fire risks, ensuring operational safety and preventing structural damage. Overall, intumescent coatings are vital for fire protection across various industries, offering high-temperature resistance and protective barriers.

Key Market Segments :

Base

- Water-based

- Solvent-based

- Epoxy-based

Type

- Thin-Film

- Thick-Film

Substrate

- Structural Steel and Cast Iron

- Wood

End-use Industry

- Building and Construction

- Automotive

- Oil Gas

- Others

Drivers :

Steel beams are essential in construction, often coated to reduce fire risk, driving the intumescent market’s growth. The popularity of wood in aesthetics and products has increased the demand for intumescent coatings to prevent combustion, fueling market expansion. Rising safety awareness and regulations also boost the market, with intumescent coatings preferred for their lightweight properties in automotive and construction industries. These coatings enhance safety while reducing the overall weight of structures, aligning with the demand for lightweight components.

Restraints :

The intumescent coatings market faces several challenges. The complex and expensive application process requires specialized techniques and skilled labor, increasing costs and hindering widespread adoption. Achieving the necessary thickness for effective fire protection can compromise aesthetic appeal, limiting their use in certain projects. Durability and performance issues arise from exposure to harsh environments and mechanical stresses, affecting longevity and effectiveness. Changing regulations and compliance standards add further challenges for manufacturers and users.

Opportunities :

The market has several growth opportunities. Increasing fire safety regulations across industries drive the demand for effective fire protection solutions like intumescent coatings. Architectural trends, especially in urban areas, require fireproof coatings that integrate with contemporary designs. The automotive industry's focus on lightweight materials for fuel efficiency aligns with the lightweight properties of intumescent coatings. Ongoing research and development in formulations can improve durability, fire protection, and address environmental concerns, opening new applications and expanding the market.

Challenges :

Despite growth potential, intumescent coatings face obstacles. The complex and costly application process requires special techniques and skilled labor, making it laborious and expensive, hindering adoption in cost-sensitive industries. Meeting the required thickness for fire protection can affect aesthetics, limiting use in design-oriented projects. Durability issues arise from exposure to harsh conditions, affecting longevity and efficiency. Regulatory changes require adjustments in composition or application methods, creating challenges for compliance. Overcoming these challenges requires innovation, technological advances, and strategic approaches to foster market expansion.