Octyl methoxycinnamate (OMC) is a widely used organic compound, primarily known for its role as a UV filter in sunscreens and personal care products. As the demand for effective and safe sun protection continues to grow, understanding the production processes and associated costs of octyl methoxycinnamate becomes increasingly important. Procurement Resource's latest report provides a comprehensive assessment of the octyl methoxycinnamate production process, offering detailed cost analysis, raw material requirements, market drivers, and key process information. This thorough examination aims to equip businesses with the knowledge they need to navigate and optimize their operations in this essential industry.

Request Free Sample - https://www.procurementresource.com/production-cost-report-store/octyl-methoxycinnamate/request-sample

Procurement Resource Assessment: Octyl Methoxycinnamate Production Process

Procurement Resource’s assessment of the octyl methoxycinnamate production process offers a meticulous analysis of each stage involved in manufacturing this vital UV filter. The report is structured to provide a clear understanding of the technical and economic aspects of octyl methoxycinnamate production, enabling stakeholders to make informed decisions based on accurate and detailed data. This assessment includes various synthesis methods, cost components, and efficiency considerations, providing a holistic view of the octyl methoxycinnamate production landscape.

Understanding Octyl Methoxycinnamate

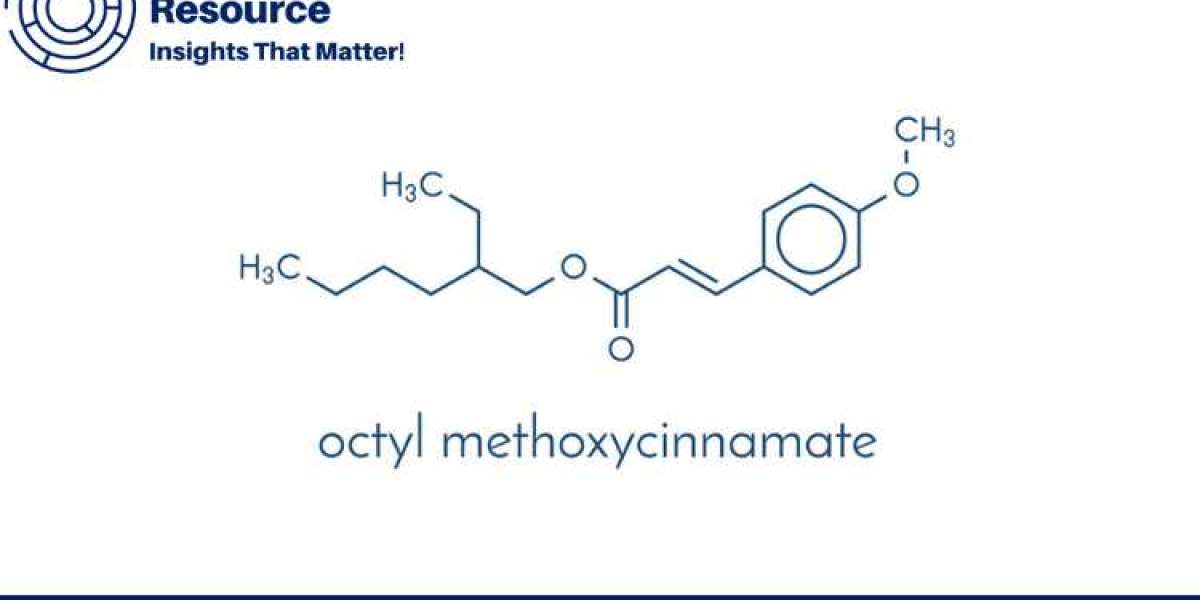

Octyl methoxycinnamate, also known as ethylhexyl methoxycinnamate, is an organic compound used as an active ingredient in many sunscreens. It works by absorbing ultraviolet (UV) radiation, thereby protecting the skin from harmful effects such as sunburn and long-term damage. OMC is highly valued in the cosmetics and personal care industry due to its effective UVB absorption properties, stability, and compatibility with other ingredients. It is also used in various formulations, including lotions, creams, and sprays.

Market Drivers

Several key factors drive the octyl methoxycinnamate market, influencing both demand and supply dynamics:

Increasing Awareness of Sun Protection: The rising awareness about the harmful effects of UV radiation and the importance of sun protection significantly boosts the demand for sunscreens and UV filters like octyl methoxycinnamate.

Growing Cosmetics and Personal Care Industry: The expanding cosmetics and personal care industry, driven by the increasing consumer demand for skincare products, directly impacts the demand for octyl methoxycinnamate.

Technological Advancements: Innovations in sunscreen formulations and the development of new and more effective UV filters enhance the market for octyl methoxycinnamate. Improved production technologies also contribute to market growth.

Regulatory Support: Regulatory guidelines and standards for sun protection products encourage the use of effective and safe UV filters, driving the demand for octyl methoxycinnamate.

Consumer Preferences for Multifunctional Products: The growing preference for multifunctional skincare products that offer sun protection, moisturizing, and anti-aging benefits increases the demand for ingredients like octyl methoxycinnamate.

Raw Materials Requirements

The primary raw materials for octyl methoxycinnamate production include:

- Methoxycinnamic Acid: A key starting material used in the synthesis of octyl methoxycinnamate.

- Octanol (2-Ethylhexanol): Used as an alcohol component in the esterification process to produce octyl methoxycinnamate.

- Catalysts and Solvents: Various catalysts and solvents are used to facilitate the esterification reaction and purify the final product.

Costs and Key Process Information

Understanding the cost structure of octyl methoxycinnamate production is crucial for optimizing operations and maximizing profitability. The key cost components include:

Raw Material Costs: The price of methoxycinnamic acid, octanol, and other chemicals significantly impacts the cost of octyl methoxycinnamate production. Fluctuations in the prices of these raw materials due to market conditions and supply chain dynamics can affect the overall production cost.

Energy Costs: The production process involves several energy-intensive steps, such as heating and distillation, which contribute significantly to the overall cost. The cost of electricity and fuel can vary based on location and energy sources.

Labor Costs: Skilled labor is required for operating synthesis and purification equipment, managing production processes, and ensuring quality control. Labor costs are influenced by the region and the level of automation in the plant.

Capital Costs: Investment in production facilities, including reactors, distillation units, and purification systems, constitutes a significant portion of the overall cost. The scale and technology used in these facilities influence capital costs.

Maintenance and Operational Costs: Regular maintenance of machinery and equipment to ensure optimal performance and prevent downtime adds to the operational costs. These also include costs for waste management, water treatment, and compliance with environmental regulations.

Key Production Stages

The octyl methoxycinnamate production process involves several key stages, each contributing to the final product's quality and cost:

- Esterification: Methoxycinnamic acid is reacted with octanol in the presence of a catalyst to form octyl methoxycinnamate. This esterification reaction typically requires controlled temperature and pressure conditions.

- Reaction Control: The reaction conditions, such as temperature, pressure, and reaction time, are carefully monitored and controlled to ensure complete esterification and high yield.

- Purification: The crude octyl methoxycinnamate is purified through processes such as distillation and recrystallization to remove any unreacted materials and by-products, achieving the desired purity.

- Drying and Formulation: The purified octyl methoxycinnamate is dried to remove any residual solvents or water and then formulated into the desired product form, such as a liquid or powder.

- Quality Control and Packaging: Rigorous quality control checks are conducted to ensure the octyl methoxycinnamate meets industry standards. The final product is packaged in suitable containers for storage and distribution.

Looking for an Exhaustive and Personalized Report?

Procurement Resource offers exhaustive and personalized reports tailored to meet the specific needs of businesses in the octyl methoxycinnamate production industry. Our comprehensive reports provide detailed insights into the production process, cost breakdowns, market dynamics, and key trends. Whether you are a manufacturer, investor, or policymaker, our reports are designed to support your strategic decisions and operational optimization.

Our personalized approach ensures that the reports are customized to address your unique business challenges and opportunities. By leveraging our extensive industry knowledge and data, we provide actionable insights that help you stay ahead of the competition and drive growth.

Conclusion

The octyl methoxycinnamate production process is intricate and requires a deep understanding of various stages, costs, and market drivers. Procurement Resource's detailed cost analysis report offers invaluable insights into this critical industry, helping businesses navigate its complexities and optimize their operations. By understanding the raw material requirements, cost components, and market dynamics, stakeholders can make informed decisions that enhance efficiency and profitability.

For an in-depth and personalized assessment of the octyl methoxycinnamate production process, tailored to your business needs, reach out to Procurement Resource. Our expertise and comprehensive analysis provide the foundation for informed decision-making and strategic planning in the octyl methoxycinnamate industry.

About Us:

Procurement Resource is an invaluable partner for businesses seeking comprehensive market research and strategic insights across a spectrum of industries. With a repository of over 500 chemicals, commodities, and utilities, updated regularly, they offer a cost-effective solution for diverse procurement needs. Their team of seasoned analysts conducts thorough research, delivering clients with up-to-date market reports, cost models, price analysis, and category insights.

By tracking prices and production costs across various goods and commodities, Procurement Resource ensures clients receive the latest and most reliable data. Collaborating with procurement teams across industries, they provide real-time facts and pioneering practices to streamline procurement processes and enable informed decision-making. Procurement Resource empowers clients to navigate complex supply chains, understand industry trends, and develop strategies for sustainable growth.

Contact Us:

Company Name: Procurement Resource

Contact Person: Amanda Williams

Email: sales@procurementresource.com

Toll-Free Number: USA Canada – Phone no: +1 307 363 1045 | UK – Phone no: +44 7537 132103 | Asia-Pacific (APAC) – Phone no: +91 1203185500

Address: 30 North Gould Street, Sheridan, WY 82801, USA