Calcium carbide (CaC₂) is a crucial industrial chemical used primarily in the production of acetylene gas and calcium cyanamide. It also finds applications in the steel industry as a desulfurizing agent and in the production of chemicals and fertilizers. Understanding the price trends of calcium carbide is essential for businesses involved in its production and use. This article provides a comprehensive analysis of the price trends of calcium carbide, covering historical prices, recent fluctuations, market dynamics, and future outlook.

Market Overview

The global market for calcium carbide is influenced by factors such as production costs, demand from key industries, and geopolitical factors. Major producers include China, the United States, and European countries, which collectively account for a significant share of global production and consumption.

Enquire For Regular Prices: https://www.procurementresource.com/resource-center/calcium-carbide-price-trends/pricerequest

Historical Price Trends

Over the past decade, calcium carbide prices have exhibited notable fluctuations. From 2010 to 2015, prices remained relatively stable, averaging around $700 to $900 per metric ton. This stability was due to consistent demand from various industries and stable production costs. However, from 2016 onwards, prices began to rise, driven by several factors:

Increased Demand: Growth in the steel and chemical industries boosted the demand for calcium carbide.Raw Material Costs: Fluctuations in the prices of raw materials such as limestone and coke impacted production costs.Regulatory Factors: Stricter environmental regulations in key producing regions affected production processes and costs.

Recent Price Trends (2023)

In 2023, calcium carbide prices ranged between $1,200 and $1,500 per metric ton. The following factors contributed to these price trends:

Supply Chain Disruptions: The COVID-19 pandemic caused significant disruptions in global supply chains, leading to shortages and increased transportation costs.Increased Production Costs: Rising energy costs and raw material prices in key manufacturing regions contributed to higher production costs.Demand Fluctuations: Demand from key end-use industries such as steel production, chemical manufacturing, and fertilizers remained strong, supporting higher prices.

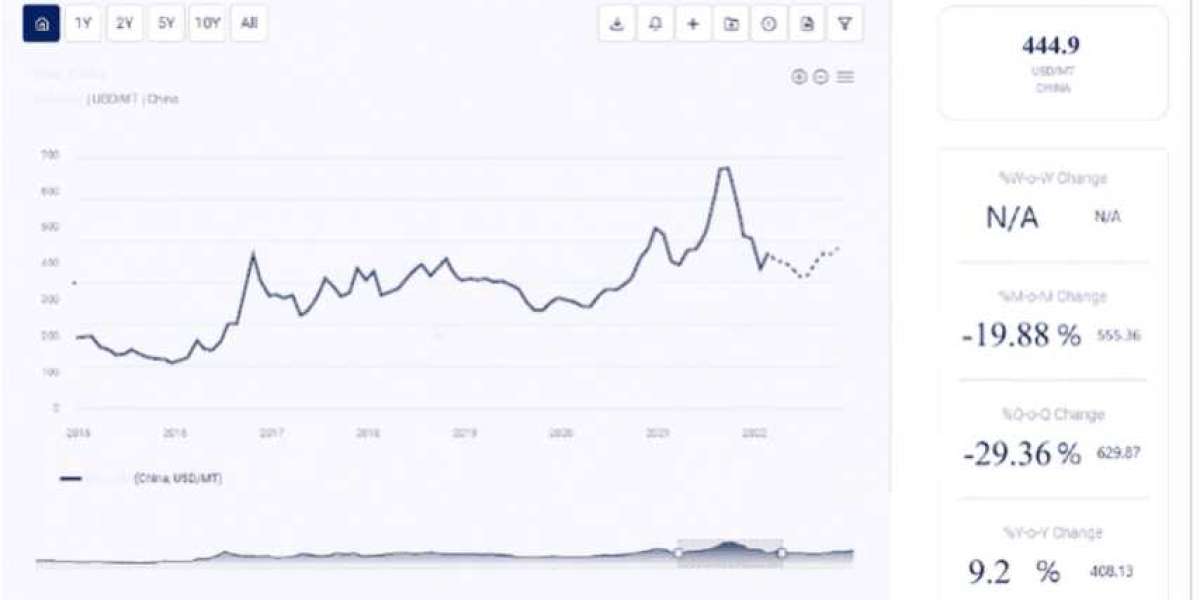

Detailed Price Chart Analysis

The chart shows a general upward trend in prices throughout the year, with minor fluctuations. Key observations include:

Steady Increase: Prices showed a steady increase from January to March, likely driven by strong demand and stable supply conditions.Mid-Year Fluctuations: April experienced a slight dip in prices, potentially due to seasonal variations or temporary supply chain improvements. However, prices quickly recovered and continued to rise through the summer months.End-Year Surge: From September onwards, there was a noticeable increase in prices, reaching the highest point in December. This could be attributed to increased demand during the end-of-year manufacturing surge and persistent supply chain challenges.

Market Dynamics

Several market dynamics influence the price trends of calcium carbide:

Supply FactorsProduction Capacity: Changes in production capacity, particularly in major producing regions like China and the United States, can significantly influence global supply and prices.Raw Material Availability: The availability and cost of key raw materials such as limestone and coke play a crucial role in determining production costs and supply levels.Supply Chain Efficiency: Efficient logistics and transportation networks are essential for maintaining stable supply and pricing. Disruptions in these networks can lead to shortages and price volatility.Demand FactorsSteel Industry: The steel industry is a significant consumer of calcium carbide, using it as a desulfurizing agent and in the production of acetylene gas.Chemical Manufacturing: Calcium carbide is used as a feedstock for various chemical reactions and processes, contributing to overall demand.Fertilizers: The agricultural industry uses calcium carbide in the production of fertilizers, driving demand.Other Industrial Applications: Calcium carbide finds use in various other industrial products and processes.

Market Trends

Technological Advancements

Advancements in production technologies and process optimization are expected to improve the efficiency and cost-effectiveness of calcium carbide production. Innovations in raw material sourcing and recycling methods may also contribute to reducing production costs.

Sustainability and Environmental Impact

Efforts to reduce the environmental impact of calcium carbide production are gaining momentum. Companies are increasingly focusing on sustainable practices, reducing emissions, and developing green alternatives. These initiatives may affect production costs and pricing.

Market Segmentation

The calcium carbide market can be segmented based on its applications:

Steel Production: The largest segment, driven by demand for desulfurizing agents and acetylene gas.Chemical Manufacturing: Used as a feedstock in chemical processes.Fertilizers: Employed in the production of agricultural fertilizers.Other Applications: Includes use in various industrial processes and products.Future Outlook

The future of the calcium carbide market looks promising, with expected growth in the steel and chemical manufacturing sectors driving demand. However, price volatility may persist due to factors such as raw material costs, regulatory changes, and geopolitical influences.

Recent DevelopmentsCapacity Expansions: Companies are investing in expanding their production capacities to meet growing demand, particularly in emerging markets.Sustainability Initiatives: Increasing focus on sustainable production methods and reducing the environmental impact of calcium carbide manufacturing.

Market Analysis

Competitive Landscape

The calcium carbide market is dominated by a few key players, including:

Inner Mongolia Baiyanhu Chemical Co., Ltd.Denka Company LimitedAlzChem Group AGSA Calcium Carbide (Pty) Ltd.Praxair Technology, Inc.Key Players

These companies are involved in the production, processing, and distribution of calcium carbide. They are focusing on strategic partnerships, technological advancements, and sustainable practices to maintain their market positions.

FAQs

Q1: What factors influence calcium carbide prices? A1: Calcium carbide prices are influenced by supply-demand dynamics, raw material costs, production capacity, regulatory restrictions, and geopolitical factors.

Q2: Which industries are the largest consumers of calcium carbide? A2: The steel production, chemical manufacturing, and fertilizer industries are the largest consumers of calcium carbide.

Q3: How do regulatory factors affect calcium carbide supply? A3: Stricter environmental regulations can increase production costs and impact supply levels, as manufacturers must invest in compliance measures and sustainable practices.

Q4: What is the future outlook for the calcium carbide market? A4: The future outlook for the calcium carbide market is positive, with expected growth driven by increased demand from the steel and chemical manufacturing sectors. However, price volatility may persist due to various influencing factors.

Conclusion

The calcium carbide market is characterized by its dependence on the steel, chemical manufacturing, and fertilizer industries. Fluctuations in supply-demand dynamics, raw material costs, and broader economic and geopolitical factors significantly influence price trends. As technological advancements and sustainability initiatives continue to evolve, the market is expected to grow, offering opportunities and challenges for stakeholders.

By diversifying supply sources, investing in technology and sustainability, and staying informed about market trends, companies can better position themselves to capitalize on opportunities and address challenges in the calcium carbide market. Effective planning and proactive management will be key to maintaining competitiveness and achieving long-term success in this evolving industry. Monitoring price trends and staying updated with industry developments will be crucial for making informed business decisions in the calcium carbide market.