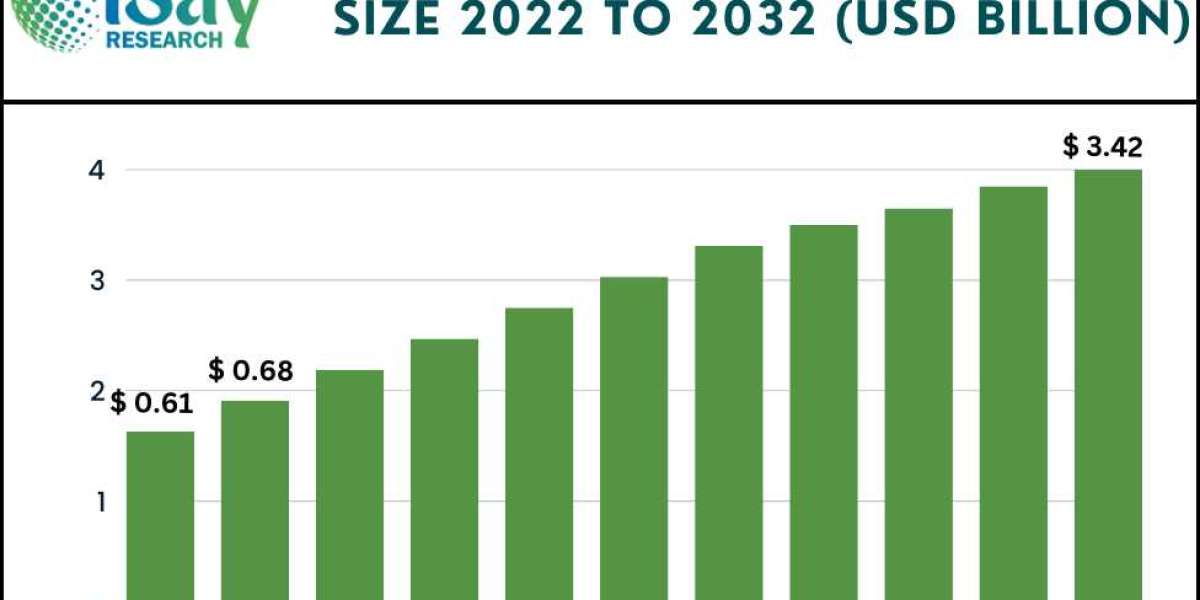

Robotic Welding Market Outlook

The global robotic welding market surged to a significant milestone, with its size climbing to nearly USD 4,501.10 million by the end of 2023. This remarkable growth is attributed to the increasing adoption of automated solutions across various industries. Looking ahead, projections indicate a robust trajectory, with the market anticipated to expand at a compound annual growth rate (CAGR) of 8.0% between 2024 and 2032. By the conclusion of this forecast period, the market is expected to reach a substantial valuation of around USD 9,192.65 million by 2032. This surge underscores the pivotal role of robotic welding in enhancing efficiency, precision, and productivity in manufacturing processes globally, driving the demand for innovative automation technologies.

Robotic Welding Market Size And Share

The global robotic welding market has demonstrated remarkable growth in recent years, buoyed by advancements in automation technology and the growing demand for efficient manufacturing processes. With industries increasingly seeking to streamline production and improve quality, robotic welding has emerged as a cornerstone solution. Its ability to enhance precision, speed, and repeatability while reducing errors and labor costs has positioned it as a vital component across various sectors, from automotive and aerospace to construction and electronics.

Get a Free Sample Report with Table of Contents@ https://www.expertmarketresearch.com/reports/robotic-welding-market/requestsample

As the market continues to evolve, several factors are driving its expansion. Technological innovations, such as improved sensor technology and artificial intelligence, are enhancing the capabilities of robotic welding systems, enabling them to handle more complex tasks with greater efficiency and accuracy. Additionally, the need for sustainable manufacturing practices is prompting industries to invest in robotic welding systems that minimize material waste and energy consumption, further fueling market growth.

Looking ahead, the global robotic welding market is poised for sustained expansion, driven by ongoing industrial automation trends and the continuous quest for operational excellence. As companies across diverse sectors recognize the competitive advantages offered by robotic welding, adoption rates are expected to rise, fostering market growth and innovation. Moreover, as emerging economies increasingly embrace industrial automation, the market is likely to witness significant opportunities for growth and penetration in previously untapped regions.

Robotic Welding Market Segmentation

The Robotic Welding Market Report and Forecast for 2024-2032 provides an extensive examination of the market, categorizing its analysis into the following segments:

Market Segmentation by Type:

- Spot Welding Robots

- Arc Welding Robots

- Others

Market Segmentation by Payload:

- Less than 50 Kg

- 50-150 Kg

- More than 150 Kg

Market Segmentation by End User:

- Automotive and Transportation

- Electrical and Electronics

- Metals and Machinery

- Aerospace and Defence

- Others

Market Segmentation by Region:

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East and Africa

Robotic Welding Market Growth Analysis

The growth analysis of the robotic welding market reveals a trajectory marked by substantial expansion and promising opportunities. Factors driving this growth include the increasing adoption of automation across industries, driven by the pursuit of enhanced efficiency, precision, and productivity. Technological advancements, particularly in sensor technology and artificial intelligence, are further bolstering the capabilities of robotic welding systems, enabling them to handle increasingly complex tasks with greater speed and accuracy.

Moreover, the market's growth is propelled by the rising demand for sustainable manufacturing practices, with robotic welding systems being instrumental in minimizing material waste and energy consumption. Industries such as automotive, aerospace, electronics, and machinery are among the primary beneficiaries of these technological advancements, driving significant market growth.

Looking ahead, the market is poised for continued expansion, fueled by ongoing industrial automation trends and the increasing recognition of the competitive advantages offered by robotic welding solutions. Emerging economies, in particular, present significant growth opportunities as they embrace industrial automation to drive efficiency and competitiveness in their manufacturing sectors. Overall, the robust growth trajectory of the robotic welding market underscores its pivotal role in shaping the future of manufacturing globally.

Robotic Welding Market Trends And Opportunities

The robotic welding market is witnessing several notable trends and opportunities that are reshaping the landscape of industrial automation:

Integration of Artificial Intelligence (AI) and Machine Learning: One prominent trend is the integration of AI and machine learning algorithms into robotic welding systems. These technologies enable robots to adapt and optimize welding parameters in real-time, leading to improved quality, efficiency, and productivity. As AI capabilities continue to advance, robotic welding systems are becoming increasingly autonomous and capable of handling complex tasks with minimal human intervention.

Collaborative Robots (Cobots): Another significant trend is the growing adoption of collaborative robots, or cobots, in welding applications. Unlike traditional industrial robots that operate in isolation, cobots can work alongside human operators, enhancing flexibility and safety in welding operations. This trend is particularly prevalent in small and medium-sized enterprises (SMEs) where space and resources are limited, as cobots offer a cost-effective and easy-to-implement solution.

Advanced Sensing and Vision Systems: Robotic welding systems are incorporating advanced sensing and vision systems to improve weld seam tracking, quality inspection, and process monitoring. These technologies enable robots to accurately locate workpieces, adjust welding parameters in real-time, and detect defects or deviations from quality standards. As the demand for high-quality welds continues to rise, the integration of sensing and vision systems presents significant opportunities for market growth.

Expansion into New End-Use Industries: While automotive and manufacturing industries have historically been the primary adopters of robotic welding technology, there is a growing trend of expansion into new end-use industries. Industries such as construction, shipbuilding, and renewable energy are increasingly turning to robotic welding solutions to improve efficiency, reduce costs, and address labor shortages. This expansion into new markets presents lucrative opportunities for robotic welding manufacturers and suppliers.

Emerging Markets and Globalization: With the increasing globalization of manufacturing operations, there is a growing demand for robotic welding solutions in emerging markets. Countries in Asia Pacific, Latin America, and the Middle East are witnessing rapid industrialization and infrastructure development, driving the adoption of robotic welding technology. As these markets continue to mature, they present significant growth opportunities for market players who can offer innovative and cost-effective solutions tailored to local needs.

Competitive Landscape

The report presents a detailed analysis of the following key players in the global Robotic Welding Market, looking into their capacity, competitive landscape, and latest developments like capacity expansions, plant turnarounds, and mergers and acquisitions:

- Fanuc Corporation

- ABB Ltd.

- Yaskawa Electric Corporation

- Kuka AG

- EVS TECH CO., LTD

- Estun Automation Co., Ltd.

- NACHI-FUJIKOSHI CORP.

- Panasonic Corporation

Read More Reports:

Global Apparel, Accessories, and Footwear Market

Top 6 Companies Leading the Global Motorcycle Market

Media Contact:

Company Name: Claight Corporation

Contact Person: Eren smith, Corporate Sales Specialist – U.S.A.

Email: sales@expertmarketresearch.com

Toll Free Number: +1-415-325-5166 | +44-702-402-5790

Address: 30 North Gould Street, Sheridan, WY 82801, USA

Website: https://www.expertmarketresearch.com